The music box mechanism has become a crucial component in industries by 2025. Its blend of precision, durability, and visual appeal has captivated manufacturers and designers alike. The global music box market is expected to grow from USD 500 million in 2023 to USD 815 million by 2032, driven by a 6.1% CAGR. Products like the Custom Wooden Music Box and Wooden Metal Music Box showcase how these music box movements combine tradition with modernity. Their use in automation, manufacturing, and product design highlights their versatility. The emotional connection to these devices further fuels demand for customized options, such as the Music Box Wooden.

Key Takeaways

- Music box parts help machines move precisely, like in robots or medical tools.

- Changing music box parts lets products play special tunes. These tunes make people feel connected to the product.

- Using eco-friendly materials makes music boxes last long and helps the planet.

Understanding the Music Box Mechanism

What Is a Music Box Mechanism

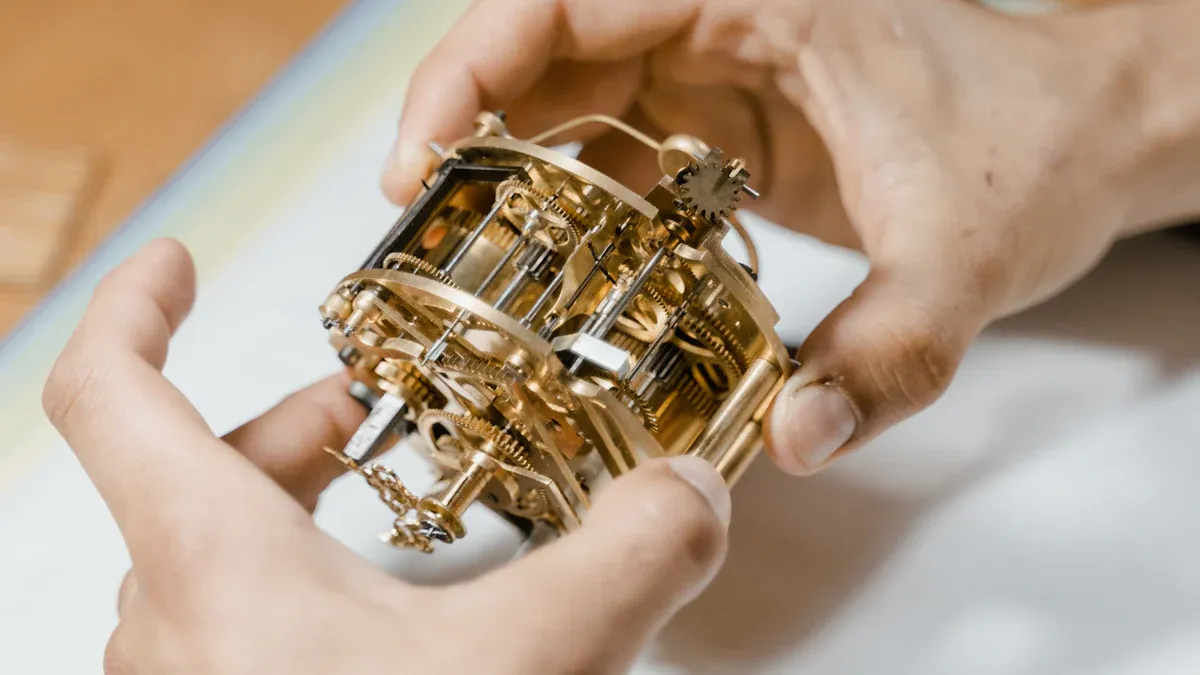

A music box mechanism is a compact mechanical device that produces melodies by plucking tuned metal teeth on a comb. The mechanism typically consists of a cylinder or disc embedded with pins, a comb with tuned teeth, and a winding mechanism. When the cylinder rotates, the pins strike the comb’s teeth, creating musical notes. This intricate design combines precision engineering with artistic craftsmanship, making it a timeless marvel.

Modern music box mechanisms have evolved to include advanced materials and designs, enhancing their durability and sound quality. These mechanisms are not only used in traditional music boxes but also integrated into industrial applications, such as automated systems and decorative product designs. Their ability to deliver consistent performance makes them valuable in precision engineering and manufacturing.

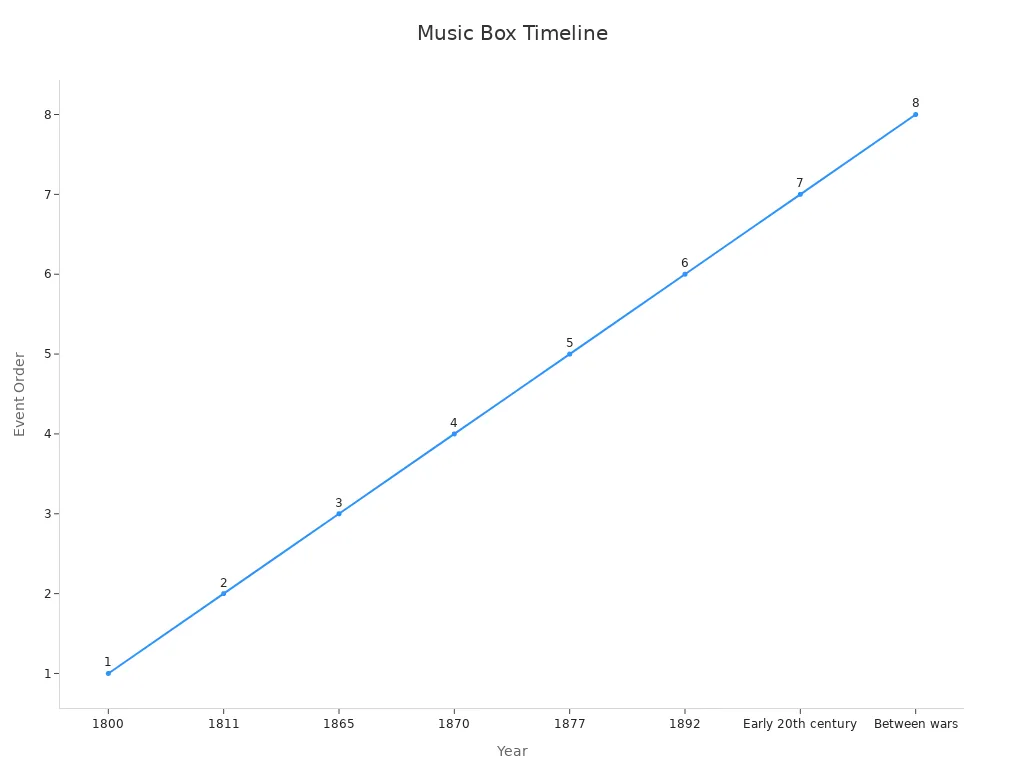

Evolution of Music Box Mechanisms for Industrial Use

The history of music box mechanisms reveals a fascinating journey of innovation and adaptation. Early examples date back to 9th-century Baghdad, where the Banū Mūsā brothers created a hydropowered organ with interchangeable cylinders. By 1811, the first music boxes were produced in Sainte-Croix, Switzerland, marking the beginning of a thriving industry.

Key milestones in the evolution of music box mechanisms include:

| Year | Milestone Description |

|---|---|

| 1800 | Isaac Daniel Piguet produces repeating musical watches with a pinned horizontal disc. |

| 1811 | First music boxes produced in Sainte-Croix, becoming a significant industry in Switzerland. |

| 1865 | Charles Reuge settles in Sainte-Croix, contributing to the pocket watch and musical movement industry. |

| 1870 | A German inventor creates a music box with discs for easier tune changes. |

| 1877 | Thomas Edison invents the phonograph, impacting the music box industry. |

| 1892 | Gustave Brachhausen establishes the Regina Music Box Company in New Jersey. |

| Early 20th century | The luxury music box industry declines due to various economic factors. |

| Between wars | Swiss companies shift to manufacturing other precise mechanical products. |

These milestones highlight the adaptability of music box mechanisms. From luxury items to industrial components, their evolution reflects the ingenuity of manufacturers and inventors. Today, companies like Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. continue to innovate, ensuring these mechanisms remain relevant in modern industries.

Industrial Applications of Music Box Mechanisms in 2025

Role in Precision Engineering

The music box mechanism plays a vital role in precision engineering. Its intricate design and ability to produce consistent mechanical movements make it a valuable tool in industries requiring high accuracy. Engineers often use these mechanisms in devices where precise timing and movement are essential. For example, they are integrated into small-scale machinery and instruments that demand exact synchronization.

The compact size of the music box mechanism allows it to fit into tight spaces without compromising performance. This feature makes it ideal for applications in robotics and medical devices. In robotics, these mechanisms help control delicate movements, such as gripping or rotating small objects. In medical devices, they contribute to the precise operation of diagnostic tools and surgical instruments.

Companies like Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. have refined the production of these mechanisms to meet the growing demand for precision engineering solutions. Their expertise ensures that each mechanism delivers reliable performance, even in challenging industrial environments.

Integration into Product Design

The music box mechanism has become a popular choice in product design due to its aesthetic and functional qualities. Designers incorporate these mechanisms into products to enhance their appeal and create a unique user experience. Items such as luxury gift boxes, jewelry cases, and decorative home accessories often feature these mechanisms to add a touch of elegance.

Incorporating a music box mechanism into a product not only improves its visual appeal but also adds an emotional connection for users. The gentle melodies produced by the mechanism evoke nostalgia and create a sense of warmth. This emotional aspect makes products more memorable and desirable.

Modern advancements have enabled designers to customize music box mechanisms to suit specific themes or preferences. For instance, a jewelry box can play a personalized tune that resonates with the owner. This level of customization has opened new opportunities for product innovation and differentiation in competitive markets.

Automation and Customization in Manufacturing

The manufacturing industry has embraced the music box mechanism for its automation and customization capabilities. These mechanisms are now used in automated assembly lines to perform repetitive tasks with precision. Their ability to operate without external power sources makes them a cost-effective solution for various manufacturing processes.

Customization has also become a key trend in manufacturing, and music box mechanisms play a significant role in this area. Manufacturers can program these mechanisms to produce specific melodies or movements, allowing them to create unique products tailored to customer preferences. This flexibility has made them a valuable asset in industries such as toy manufacturing and personalized gift production.

Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. has been at the forefront of integrating music box mechanisms into manufacturing processes. Their innovative designs and commitment to quality have helped industries achieve greater efficiency and customization. By combining traditional craftsmanship with modern technology, they continue to push the boundaries of what these mechanisms can achieve.

Advantages of Using Music Box Mechanisms

Durability and Sustainability

Music box mechanisms are renowned for their durability, making them ideal for long-term industrial use. Manufacturers often construct these mechanisms using high-quality materials like metal and wood, which resist wear and tear. This durability ensures consistent performance even in demanding environments.

Sustainability is another key advantage. Wooden components, often sourced from renewable materials, reduce the environmental impact of production. Companies like Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. prioritize eco-friendly practices by incorporating sustainable materials into their designs. This approach aligns with the growing demand for greener industrial solutions.

Precision and Reliability in Industrial Settings

The music box mechanism excels in delivering precise and reliable performance. Its intricate design ensures accurate movements, which are critical in industries like robotics and medical technology. For example, these mechanisms enable robots to perform delicate tasks with precision, such as assembling small components or handling fragile materials.

Reliability is equally important. These mechanisms operate consistently over time, reducing the need for frequent maintenance. This reliability makes them a cost-effective choice for industries that require uninterrupted operation. Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. has perfected the art of producing mechanisms that meet these high standards, ensuring their widespread adoption in industrial applications.

Aesthetic and Functional Benefits

Music box mechanisms offer a unique blend of aesthetic and functional advantages. Designers often choose these mechanisms to enhance the visual appeal of products while maintaining their functionality. The choice of materials plays a significant role in achieving this balance:

| Material Type | Aesthetic Benefits | Functional Benefits |

|---|---|---|

| Wood | Natural warmth and beauty; enhances acoustic properties | Produces rich and warm tone; better sound quality with harder woods |

| Plastic | Lightweight; customizable shapes and designs | Cost-effective; suitable for lower-cost models, but lower tone quality |

| Composite | Combines benefits of different materials | Balances cost, durability, and sound quality; tailored for specific needs |

Wooden music box mechanisms, for instance, create a warm and nostalgic feel, while composite materials offer a balance of durability and sound quality. This versatility allows manufacturers to tailor products to specific customer preferences, making them both functional and visually appealing.

Innovations and Future Trends in Music Box Mechanisms

Technological Advancements in Mechanism Design

Music box mechanisms have undergone significant technological advancements, transforming their design and functionality. Modern mechanisms incorporate precision engineering techniques to improve sound quality and durability. Engineers now use computer-aided design (CAD) software to create intricate components with unparalleled accuracy. This innovation ensures consistent performance across various applications.

Materials used in music box mechanisms have also evolved. Manufacturers increasingly use composite materials to balance durability and acoustic properties. These materials enhance the sound quality while reducing wear and tear. Additionally, advancements in microelectronics have enabled the integration of programmable features. Users can now customize melodies or control mechanisms through digital interfaces, adding versatility to traditional designs.

Companies like Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. lead the way in adopting these technologies. Their commitment to innovation ensures that music box mechanisms remain relevant in modern industries. By combining traditional craftsmanship with cutting-edge technology, they continue to push the boundaries of design and functionality.

Emerging Industrial Applications

The versatility of music box mechanisms has opened doors to new industrial applications. These mechanisms are now used in products that combine functionality with aesthetic appeal. Emerging applications illustrate their potential to transform industries:

| Application Type | Description |

|---|---|

| Smart Music Boxes | Connect with devices, programmable to play specific songs, and may include voice-activated controls. |

| Personalized Music Boxes | Customized with names, dates, or messages, appealing for unique gifts. |

| Interactive Music Boxes | Use sensors to trigger sounds or melodies, engaging users through movement. |

| Sustainable Music Boxes | Made from eco-friendly materials, appealing to environmentally conscious consumers. |

Smart music boxes represent a leap forward in functionality. These devices connect to smartphones or other gadgets, allowing users to program melodies or activate mechanisms with voice commands. Personalized music boxes cater to the growing demand for unique gifts, offering customization options that resonate with individual preferences.

Interactive music boxes engage users through motion sensors, creating an immersive experience. Sustainable music boxes align with environmental trends, using renewable materials to reduce ecological impact. These applications highlight the adaptability of music box mechanisms in meeting diverse consumer needs.

Overcoming Challenges and Exploring Opportunities

Despite their growing popularity, music box mechanisms face challenges that require innovative solutions. One challenge involves balancing traditional craftsmanship with modern technology. Manufacturers must preserve the nostalgic appeal of music boxes while integrating advanced features.

Another challenge lies in scaling production to meet increasing demand. Precision engineering requires meticulous attention to detail, which can slow manufacturing processes. Companies like Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. address this issue by optimizing production techniques. Their expertise ensures high-quality mechanisms without compromising efficiency.

Opportunities abound in expanding the use of music box mechanisms across industries. Designers can explore new applications in wearable technology, where compact mechanisms add functionality to accessories. The rise of smart homes offers another avenue for innovation, with music box mechanisms integrated into decorative devices that enhance living spaces.

By overcoming challenges and seizing opportunities, manufacturers can unlock the full potential of music box mechanisms. Their ability to combine tradition with innovation ensures a bright future for this timeless technology.

Music box mechanisms have become indispensable in industrial applications. Their precision, durability, and aesthetic appeal make them versatile tools across various sectors. These mechanisms enhance product design, improve manufacturing processes, and inspire innovation. Companies like Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. drive this progress by blending traditional craftsmanship with modern technology, ensuring a bright future for these timeless devices.

FAQ

What industries benefit most from music box mechanisms?

Music box mechanisms enhance precision engineering, product design, and manufacturing. Industries like robotics, medical devices, and personalized gifts utilize their accuracy and aesthetic appeal.

How do music box mechanisms contribute to sustainability?

Manufacturers use renewable materials like wood and eco-friendly composites. These practices reduce environmental impact while maintaining durability and functionality.

Can music box mechanisms be customized for specific applications?

Yes, manufacturers program melodies and movements to meet unique needs. Customization enables tailored solutions for toys, luxury items, and automated systems.

Post time: May-14-2025