Automation e fetotse tsela eo bahlahisi ba netefatsang boleng ba eona mecheng ea mabokose a mmino. Lintlafatso tsa morao-rao li totobatsa bokhoni ba eona ba ho ntlafatsa ho nepahala le ho fokotsa liphoso tsa batho ka mekhoa e mecha:

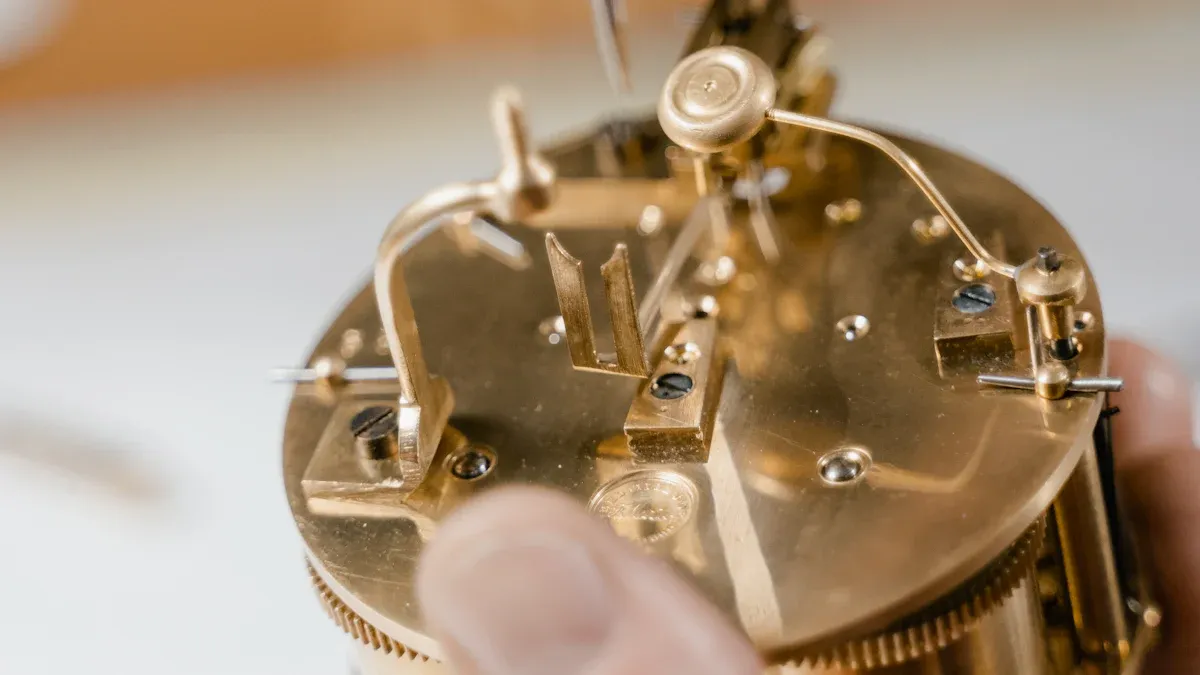

- Khatiso ea 3D e theha libopeho tse rarahaneng ka ho nepahala ho ke keng ha lekanngoa, ea bohlokoa bakeng sa likarolo tse tieang tsa amochine oa lebokose la 'mino.

- Mehaho e entsoeng bocha e ntlafatsa ts'ebetso likarolong tsohle tsa bohlokoa joalo ka cylinder e pentiloeng le kama.

- Likhetho tsa thepa, joalo ka PLA le li-spacers tsa tšepe, li matlafatsa boleng ba molumo haholomabokose a 'mino a tloaelehileng.

Litlhahiso tsena li etsa hore tlhahiso e atlehe haholoanyane, e netefatsa boleng bo tsitsitseng ka mabokoseng a 'mino a mechine lemetsamao ya mabokose a mmino bakeng sa mesebetsi ya matsoho.

Lintlha tsa bohlokoa

- Automation e etsa lebokose la mminoho etsa hore e nepahale ho feta. E theola liphoso mme e netefatsa hore likarolo tsohle li finyella litekanyetso tse phahameng.

- Ho sebelisa pono ea mochinee thusa ho fumana mefokolo habonolo. Sena se lekola likaroloana tse nyane ho boloka boleng le ts'ebetso e tsitsitse.

- Automation e boloka nako le chelete. Licheke tse potlakileng le litšila tse fokolang li bolela ho boloka chelete e ngata le phaello e ngata.

Mathata a Taolo ea Boleng bakeng sa Mechane ea Lebokose la Mmino

Meeli ea Litlhahlobo ka Matsoho

Phoso ea motho ea ho lemoha mefokolo mecheng e rarahaneng ea mabokose a mmino

Litlhahlobo tsa matsohohangata ho thata ho lemoha mefokolo ea likarolo tse bonolo tsa mochine oa lebokose la 'mino. Popego e e raraaneng ya dikarolo tse di jaaka moqomo o o pinilweng le kama e tlhoka selekanyo se se tlhomameng se matlho a motho a ka se kgoneng go se fitlhelela ka metlha. Leha ho le joalomefokolo e nyane e ka sitisa tšebetso ea acoustic, e lebisang ho boleng ba molumo o tlase. Ho itšetleha hona ka mekhoa ea matsoho ho eketsa menyetla ea liphoso, haholo-holo ha ho hlahlojoa mekhoa e mengata.

Boleng bo sa tsitsang ka lebaka la tlhahlobo ea matsoho e ikemetseng

Boikemisetso ba ho hlahloba ka matsoho bo baka ho se lumellane ho boleng ba sehlahisoa. Bahlahlobi ba fapaneng ba ka sebelisa litekanyetso tse fapaneng, tse bakang litekanyetso tse sa lekanang. Ho se lumellane hona ho hlahisa liphephetso ho bahlahisi ba ikemiselitseng ho fihlela litekanyetso tse thata tsa machaba tsa polokeho le boleng. Baetsi ba banyenyane, haholo-holo, ba tobana le litšitiso ka lebaka la litšenyehelo tse phahameng tse amanang le tlhahlobo e matla le ho latela melao.

Tšusumetso ho Liphetho tsa Tlhahiso

Litsenyehelo tse phahameng tsa tlhahiso ho tsoa ho ho se sebetse hantle

Ho se sebetse hantle ha mekhoa ea taolo ea boleng ba matsoho ho kenya letsoho holitšenyehelo tse phahameng tsa tlhahiso. Litlhahlobo tse phetoang khafetsa le lipotoloho tsa tšebetso li ja nako le lisebelisoa tsa bohlokoa. Ho se sebetse hantle hona ho ka senya lichelete tsa lichelete, haholo-holo bakeng sa bahlahisi ba hlahisang mekhoa e rarahaneng ea lebokose la 'mino ka tekanyo e kholo.

Ho lieha ho hloaea le ho rarolla mathata, ho ama ts'epahalo ea sehlahisoa

Ho hlahloba ka letsoho hangata ho hloleha ho lemoha mefokolo pele ho nako ea tlhahiso. Ho lieha ho tsebahatsa litaba ho ka senya botšepehi ba sehlahisoa sa ho qetela. Bareki ba lebelletse boleng bo ts'oanang, 'me tieho ea ho sebetsana le liphoso e ka senya botumo ba lebitso le ts'epo ea bareki.

Hlokomela:Ho sebetsana le mathata ana ho hloka ho amohela litharollo tse ikemetseng tse ntlafatsang ho nepahala, ho fokotsa litšenyehelo, le ho netefatsa boleng bo tsitsitseng ho pholletsa le mekhoa eohle ea mabokose a 'mino.

Melemo ea ho iketsetsa Taolo ea Boleng ka har'a Music Box Mechanism Manufacturing

Ntlafatso ea ho Nepa le ho Nepaha

Sistimi ea othomathike e lemoha mefokolo e nyane mme e netefatsa hore mamello ea likarolo e fihlella litekanyetso tse thata

Automation e hlahisa litsamaiso tse tsoetseng pele tse khonang ho tseba liphoso tse nyane tseo tlhahlobo ea matsoho hangata li e hlokomolohang. Litsamaiso tsena li netefatsa hore karolo e 'ngoe le e 'ngoe ea amochine oa lebokose la 'minoe khomarela mamello e tiileng, e boloka botsitso bo rarahaneng bo hlokahalang bakeng sa ts'ebetso e nepahetseng. Ka ho lemoha liphoso esale pele, bahlahisi ba ka thibela likarolo tse nang le phoso ho tsoela pele ka mohala oa tlhahiso, ho sireletsa boleng ba sehlahisoa sa ho qetela.

Theknoloji ea pono ea mochini e lekola mekhoa e rarahaneng ka nepo e ke keng ea lekanngoa

Theknoloji ea pono ea mochini e fetola mokhoa oa ho hlahloba ka ho sebelisa lik'hamera tse nang le qeto e phahameng le tlhahlobo ea litšoantšo e tsamaisoang ke AI. Theknoloji ena e ipabola tabeng ea ho hlahloba likarolo tse rarahaneng tsa mochine oa lebokose la ’mino, tse kang moqomo o pentiloeng le kama, ka ho nepahala ho ke keng ha bapisoa. Ho fapana le bahlahlobi ba batho, litsamaiso tsa pono tsa mochini li boloka ho nepahala ho sa fetoheng, ho netefatsa hore esita le mefokolo e menyenyane ka ho fetisisa e tsejoa le ho rarolloa kapele.

Sebetsa se Ntlafetseng le Poloko ea Litšenyehelo

Mekhoa ea ho hlahloba ka potlako e fokotsa nako ea tlhahiso

Taolo ea boleng bo ikemetseng e potlakisa haholo ts'ebetso ea tlhahlobo. Mechini e ka lekola likarolo tse ngata ka nako e le 'ngoe, e fokotsa nako e hlokahalang bakeng sa tlhahlobo e phethahetseng. Ts'ebetso ena e lumella bahlahisi ho eketsa litefiso tsa tlhahiso ntle le ho senya boleng, ho fihlela litlhoko tsa 'maraka ka katleho.

Automation e fokotsa tšenyo le ho theola litšenyehelo tsa basebetsi, e eketsa phaello

Ka ho fokotsa liphoso tsa batho, boits'oaro bo fokotsa litšila le ho sebetsa hape. E boetse e theola litšenyehelo tsa basebetsi ka ho nolofatsa mesebetsi e ipheta-phetang, e nolofalletsang basebetsi ho tsepamisa maikutlo mesebetsing e rarahaneng haholoanyane. Ho latela lintlha tsa indasteri, boiketsetso bo ka fokotsa litšenyehelo tsa tlhahiso ka kakaretso ka 30-50% le litšenyehelo tsa thepa ho fihla ho 45%. Lipolokelo tsena li eketsa phaello ka kotloloho, 'me li etsa hore boiketsetso e be letsete la bohlokoa bakeng sa bahlahisi.

| Molemo | Metric/Phesente |

|---|---|

| Phokotso ea Litšenyehelo | 15-25% taolong ea phepelo ea thepa |

| 30-50% ka kakaretso | |

| 10-40% ka litšenyehelo tsa tlhokomelo | |

| 15-20% ea ho boloka nako ea basebetsi ba HR | |

| Litšenyehelo tsa ho tsamaisa thepa | Ho fihlela ho 45% phokotso |

| Litšenyehelo tsa litšebeletso tsa bareki | 30-60% ea fokotseha |

| Ntlafatso ea ho Nepaha | 60% e fokolang liphoso tsa batho |

| Ho nepahala ha taolo ea boleng | 94.5-96% ho nepahala ha bofokoli ba ho bolela esale pele |

| Ho nepahala ha tlhahlobo ea AI | 99.9% ha e bapisoa le 80-90% bakeng sa batho |

Boleng bo lumellanang ba Sehlahisoa

E netefatsa hore mochini o mong le o mong oa lebokose la 'mino o kopana le maemo a holimo, o ntlafatsa khotsofalo ea bareki le botumo ba lebitso

Automation e etsa bonnete ba hore mochine o mong le o mong oa lebokose la 'mino o finyella litekanyetso tse tšoanang tsa boleng bo phahameng. Ho tsitsisa boleng ho ntlafatsa khotsofalo ea bareki, kaha bareki ba fumana lihlahisoa tse tšepahalang tse sebetsang kamoo ho lebeletsoeng. Ho tšepahala hona ho matlafatsa botumo ba brand, ho beha baetsi ba maemo joalo ka Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. joalo ka baetapele ba indasteri. Ka ho fana ka lihlahisoa tse phahameng, lik'hamphani li ka haha botšepehi ba bareki ba nako e telele 'me tsa fumana moeli oa tlhōlisano' marakeng.

Key Technologies Driving Automation in Music Box Mechanism Manufacturing

Mechine ea Pono ea Mechini

Lik'hamera tse nang le qeto e phahameng le tlhahlobo ea litšoantšo tse tsamaisoang ke AI bakeng sa ho lemoha liphoso

Sistimi ea pono ea mochini e bapala karolo ea bohlokoa ho iketsetsa taolo ea boleng bakeng samekhoa ea lebokose la 'mino. Litsamaiso tsena li sebelisa lik'hamera tsa boemo bo holimo ho nka litšoantšo tse qaqileng tsa likarolo. Tlhahlobo e tsoetseng pele ea litšoantšo e tsamaisoang ke AI e ntan'o sebetsa litšoantšo tsena ho bona mefokolo e ka 'nang ea se ke ea bonoa ke batho. Theknoloji ena e supa ho se phethahale ha maemo a manyane, joalo ka lithakhisa tse sa lumellaneng hantle kapa meno a sa tloaelehang a kama, ho netefatsa hore karolo e 'ngoe le e 'ngoe e fihlela litekanyetso tse tiileng tsa boleng. Ka ho kopanya pono ea mochine, bahlahisi ba ka finyella ho nepahala ho ke keng ha bapisoa ho lemoha sekoli.

E thusa ho hlahloba likarolo tse rarahaneng ho netefatsa ts'ebetso

Moralo o rarahaneng oa mochini oa lebokose la 'mino o hloka tlhahlobo e nepahetseng ho netefatsa ts'ebetso. Sistimi ea pono ea mochini e sebetsa hantle sebakeng sena ka ho sekaseka likarolo tse rarahaneng joalo ka moqomo o hahelletsoeng le kama ka nepo e ikhethang. Litsamaiso tsena li lekola boholo, tekano, le boleng ba bokaholimo, ho netefatsa hore karolo ka 'ngoe e sebetsa ka kutloano. Boemo bona ba tlhahlobo bo tiisa hore sehlahisoa sa ho qetela se fana ka boleng ba molumo o lakatsehang le ts'ebetso ea mochini, e matlafatsang khotsofalo ea bareki.

IoT le Sensor Integration

Tlhokomelo ea nako ea 'nete ea likarolo tsa mochini bakeng sa ho lemoha mefokolo ea pele

Marang-rang a Lintho (IoT) le khokahano ea sensor e thusa ho lekola likarolo tsa mochini nakong ea tlhahiso. Li-sensor tse kentsoeng ka har'a lisebelisoa tsa tlhahiso li bokella datha ho li-parameter tse kang vibrate, mocheso le tekano. Lintlha tsena li thusa ho tseba liphoso tse ka bang teng qalong ea ts'ebetso, ho thibela likarolo tse fosahetseng ho tsoela pele ka mokhoa oa tlhahiso. Ka ho rarolla mathata hang-hang, bahlahisi ba ka fokotsa litšila 'me ba boloka botšepehi ba mekhoa ea bona ea' mino oa 'mino.

Ho bokella le ho hlahloba lintlha ho ntlafatsa mekhoa ea tlhahiso

Sistimi ea IoT ha e bone liphoso feela empa e boetse e bokella lintlha tsa bohlokoa nakong eohle ea tlhahiso. Lintlha tsena li fana ka leseli mabapi le ts'ebetso ea lisebelisoa, ts'ebeliso ea thepa, le ts'ebetso e sebetsang hantle. Baetsi ba ka sekaseka tlhahisoleseling ena ho tseba mekhoa, ho ntlafatsa phallo ea mosebetsi, le ho ntlafatsa tlhahiso ka kakaretso. Mohlala, tlhahlobo ea datha e ka bonts'a mekhoa ea bofokoli, e lumella lik'hamphani ho fetola lits'ebetso tsa tsona ho fokotsa liphoso. Mokhoa ona oa proactive o ntlafatsa boleng le katleho.

Liroboto Kopanong le Tlhahlobong

Matsoho a liroboto bakeng sa ho ts'oara hantle le ho kopanya mekhoa e metle ea mabokose a mmino

Matsoho a liroboto a fetotse mokhoa oa kopano bakeng sa mekhoa ea lebokose la 'mino. Liroboto tsena li sebetsana le likarolo tse bonojoana ka nepo, li netefatsa hore li behiloe ka nepo le ho tsamaisana hantle. Bokhoni ba bona ba ho etsa mesebetsi e pheta-phetoang ka ho nepahala ho tsitsitseng ho fokotsa kotsi ea tšenyo ea likarolo tse senyehang. Mohlala, matsoho a liroboto a ka kopanya moqomo o hanngoeng le ho kama ka ho mamellana hantle, ho boloka botsitso bo rarahaneng bo hlokahalang bakeng sa tlhahiso e nepahetseng ea molumo.

Mekhoa ea ho hlahloba e ikemetseng ho boloka boleng bo tsitsitseng

Ntle le kopano, liroboto li bapala karolo ea bohlokoa tlhahlobong e ikemetseng. Liroboto tse nang le li-sensor tse tsoetseng pele le lik'hamera li ka lekola lihlahisoa tse felileng bakeng sa bofokoli, ho netefatsa boleng bo ts'oanang ho likarolo tsohle. Litlhahlobo tsena tsa boiketsetso li felisa ho feto-fetoha le maemo, li fana ka liphetho tse tšepahalang nako le nako. Ka ho kopanya liroboto ho kopano le tlhahlobo, bahlahisi ba ka tsamaisa ts'ebetso le ho ntlafatsa boleng ba mekhoa ea bona ea mabokose a mmino.

Mehato ea ho Kenyelletsa Boiketsetso ho Tlhahiso ea Mokhoa oa Lebokose la Mmino

Hlahloba Mekhoa ea Hona Joale

Hlalosa litšitiso le ho se sebetse hantle taolong ea boleng ba matsoho

Mohato oa pele oa ho kenya ts'ebetsong othomathike o kenyelletsa tlhahlobo e phethahetseng ea lits'ebetso tse teng. Baetsi ba lokela ho hlwaya litšitiso tse liehisang tlhahiso le ho se sebetse hantle taolong ea boleng ba matsoho. Mohlala, tlhahlobo e pheta-phetoang kapa lipotoloho tsa ho sebetsa bocha hangata li ja nako le lisebelisoa tse ngata. Ka ho supa litaba tsena, lik'hamphani li ka tseba hore na othomathike e tla ba le tšusumetso e kholo hokae.

Lekola likhaello tsa liphoso le libaka tsa ntlafatso

Ho hlahloba litekanyetso tsa sekoli ho fana ka lintlha tsa bohlokoa ka boleng ba mekhoa ea hona joale ea tlhahiso. Baetsi ba lokela ho hlahloba lintlha tsa histori ho tseba mekhoa ea mefokolo le libaka tse hlokang ntlafatso. Tlhahlobo ena e thusa ho etelletsa pele boiteko ba ho iketsetsa, ho netefatsa hore lintlha tse bohloko tse bohloko, tse kang ho hlahloba likarolo tse rarahaneng ka mochine oa lebokose la 'mino, li sebetsanoa pele.

Khetha lisebelisoa tse nepahetseng tsa Automation

Khetha mekhoa ea theknoloji e tsamaellanang le litlhoko tse khethehileng tsa tlhahiso ea mochine oa lebokose la 'mino

Ho khetha lisebelisoa tse nepahetseng ho bohlokoa bakeng sa othomathike e atlehileng. Baetsi ba lokela ho tsepamisa maikutlo ho theknoloji e etselitsoeng litlhoko tse ikhethang tsa tlhahiso ea mochine oa lebokose la 'mino. Mohlala, litsamaiso tsa pono ea mochini le matsoho a liroboto li loketse ho lekola le ho kopanya likarolo tse bobebe. Litharollo tse hlophisitsoeng li netefatsa hore li-automation li ikamahanya le lipheo tsa tlhahiso le ho ntlafatsa katleho ka kakaretso.

Etsa bonnete ba hore scalability le ho lumellana le litsamaiso tse teng

Lisebelisoa tsa othomathike li tlameha ho hokahana ka mokhoa o se nang moeli le litsamaiso tsa hajoale tsa tlhahiso. Scalability ke taba e 'ngoe ea bohlokoa, kaha litlhoko tsa tlhahiso li ka eketseha ha nako e ntse e ea. Ho khetha mahlale a feto-fetohang ho lumella bahlahisi ho holisa bokhoni ba bona ba boiketsetso ntle le litšitiso tse kholo. Mokhoa ona o netefatsa ho ikamahanya le maemo nako e telele le ho boloka litšenyehelo.

Basebetsi ba Terene le ho hlokomela Ts'ebetso

Fana ka lithupelo tse felletseng bakeng sa li-operators le litheknishiene

Koetliso e bapala karolo ea bohlokoa ts'ebetsong e atlehileng ea automation. Basebelisi le litsebi li tlameha ho utloisisa mokhoa oa ho sebelisa le ho boloka litsamaiso tse ikemetseng ka nepo. Mananeo a koetliso a tlameha ho akaretsa likarolo tse kang ho rarolla mathata, ho lekanya tsamaiso, le tlhaloso ea lintlha. Basebetsi ba koetlisitsoeng hantle ba fokotsa nako ea ho theoha 'me ba etsa bonnete ba hore ts'ebetso e sebetsa hantle.

| Mofuta oa Bopaki | Tlhaloso |

|---|---|

| Leeme ho Data | Litšebelisano tsa batho li ka hlahisa leeme ho li-datasets, e hlokang tlhahlobo e hlokolosi. |

| Ho rarahana ha Mohlala | Sebopeho sa black box sa mehlala ea ho ithuta e tebileng e totobatsa tlhokahalo ea koetliso ea basebetsi. |

| Litlhaselo Tsa Bahanyetsi | Koetliso e lokisetsa basebetsi ho fokotsa likotsi tse kang ho hlaseloa ke bahanyetsi ho mehlala. |

Tsoela pele ho beha leihlo le ho ntlafatsa litsamaiso tse ikemetseng bakeng sa ts'ebetso e phahameng

Automation e hloka tlhahlobo e tsoelang pele ho boloka ts'ebetso e phahameng. Litlhahlobo tse tloaelehileng tsa sistimi li thusa ho tseba libaka tseo motho a ka li ntlafatsang, joalo ka mokhoa oa ho lokisa litsamaiso tsa pono ea mochini kapa ho lokisa matsoho a roboto. Tlhokomelo e sebetsang e etsa bonnete ba hore litsamaiso tse ikemetseng li tsoela pele ho fana ka boleng bo tsitsitseng le katleho ha nako e ntse e ea.

Taolo ea boleng e iketsang e fetohatlhahiso ea mochine oa lebokose la 'minoka ho etsa bonnete ba ho nepahala, ho sebetsa hantle, le ho boloka litšenyehelo.

Likhamphani tse kang Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. li sebelisa li-automation ho fana ka boleng bo holimo ba sehlahisoa, ho tsamaisa ts'ebetso, le ho eketsa phaello. Boitlamo ba bona ba popontshwa bo ba beha maemong a ho ba baetapele indastering, ba bea maemo a ho tshepahala le kgotsofalo ya bareki.

Nako ea poso: May-23-2025 .

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur